Stimson Lumber's representatives will host a community meeting to outline plans to build a new structure at their mill near Hagg Lake Tuesday, March 4.

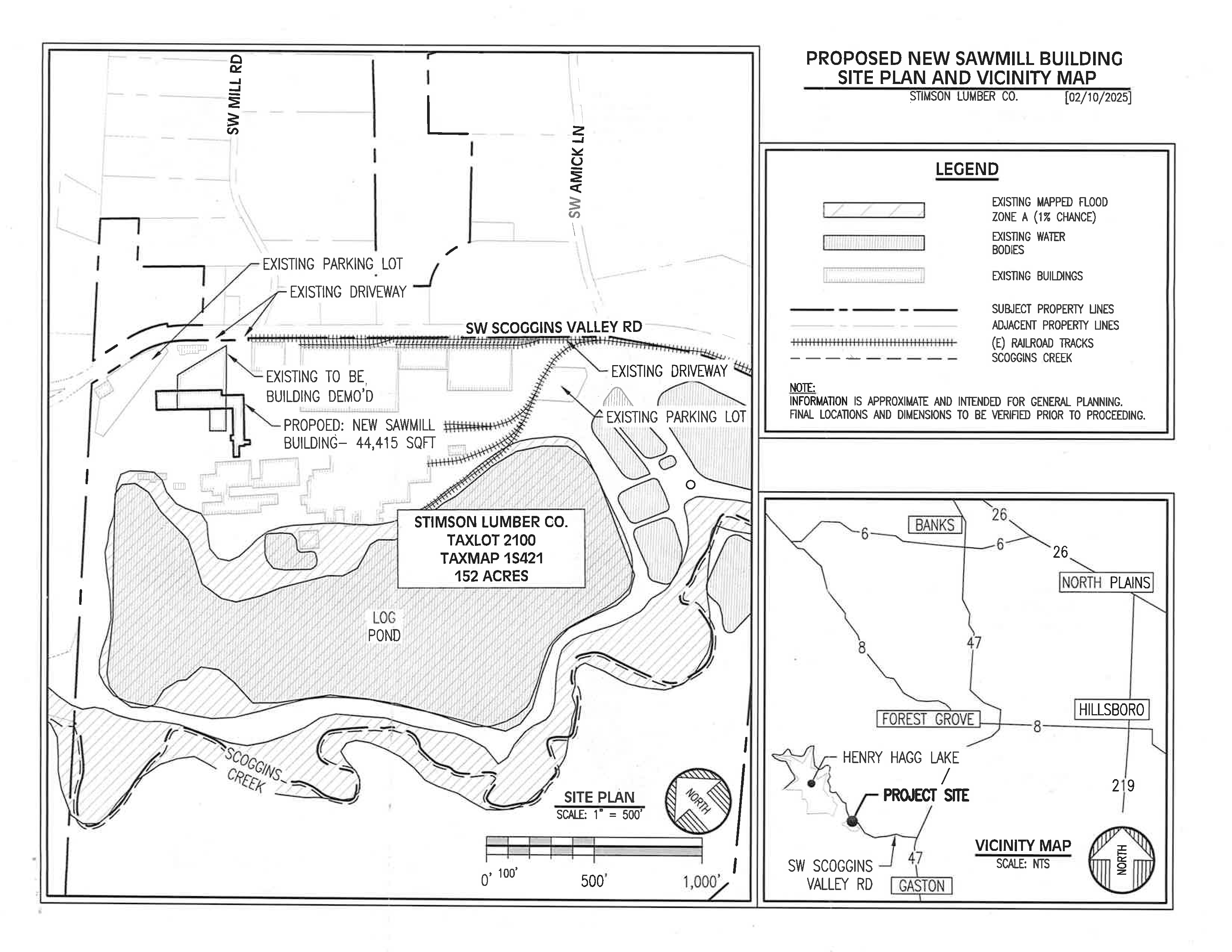

"We are considering a proposal to add a new 45,000 square-foot small-log sawmill building to our existing sawmill facility," a representative for Stimson Lumber said in a letter. "The new building would take the place of an existing 60,000 square-foot warehouse building, which would be demolished," the letter read.

According to documents obtained by this newspaper through a public records request made to Washington County Land Use and Transportation, the footprint of the existing sawmill would not be expanded.

The company lists the site as their Forest Grove mill; it's located in the former Scoggins Valley community near Hagg Lake with a Gaston mailing address.

A community meeting to give locals an overview of current plans — which are preliminary and could change — is scheduled for Tuesday, March 4 from 6 to 8 p.m. at Wapato Valley Church (also known as "The Hub") at 200 Front Street in Gaston.

The meeting is hosted by Lower Columbia Engineering, who are representing Stimson Lumber in developing the project.

In a June 2024 press release, Stimson Lumber said the company would invest $50 million into building a high-speed sawmill for smaller-dimension timber.

The new mill building, if approved, will house a 350-foot-long HewSaw line made by Finland-based company Veisto-Oy.

The company believes the new line will be operational in 2026, and that the existing line will continue operating without pause during construction.

“We are excited about the investment in this new technology for multiple reasons,” Stimson Lumber Company Chief Executive Officer Andrew Miller said. “On one hand, we are committing to long-term operations at Stimson’s oldest mill site, and the economic and workforce impacts the mill brings to the community.”

“This technology also represents an opportunity for Stimson and other timberland owners to efficiently process smaller diameter timber that previously would have been sold for pulp rather than be cut into dimensional lumber, or timber that would have to grow for another eight years before becoming marketable. We think this will be a real win for landowners,” Miller said.

The new sawline will process logs between four inches and 16 inches in diameter at a rate of 70 eight-foot-blocks per minute, a speed that, according to Miller, will make it the highest speed sawline in North America.

“The new mill will be one of the most efficient and productive sawmills in North America, which is Stimson’s goal with the investment,” Miller says.

Tuesday's community meeting is a required step before Stimson can move forward with the land use process.